I-PVC Ukukhiqiza

Ngokuyisisekelo, imikhiqizo ye-PVC yenziwa ngempushana eluhlaza ye-PVC ngenqubo yokushisa nokucindezela.Izinqubo ezimbili ezinkulu ezisetshenziswa ekukhiqizeni i-extrusion yepayipi nokubumba umjovo wokufakwa.

Ukucubungula kwe-PVC yesimanje kuhilela izindlela zesayensi ezithuthuke kakhulu ezidinga ukulawula okunembile kokuguquguquka kwenqubo.Impahla ye-polymer iyimpushana egelezayo yamahhala, edinga ukwengezwa kwama-stabilizer kanye nezinsiza zokucubungula.Ukwakhiwa nokuhlanganisa kuyizigaba ezibalulekile zenqubo futhi ukucaciswa okuqinile kugcinwa izinto ezingavuthiwe ezingenayo, ukuhlanganisa kanye nokuxuba.Okuphakelayo emishinini yokukhipha noma yokubumba kungase kube okuqondile, ngendlela "yengxube eyomile", noma kucutshungulwe ngaphambili "kuhlanganisela" we-granular.

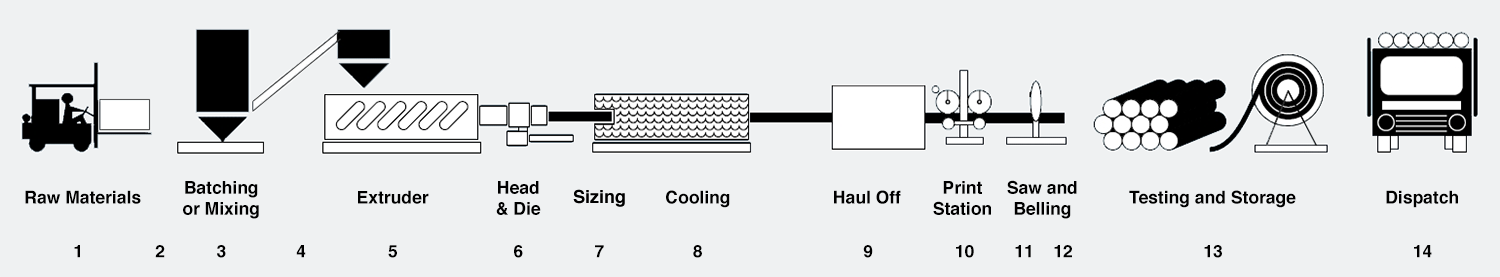

I-Extrusion

I-polymer nezithasiselo (1) zikalwa ngokunembile (2) futhi zicutshungulwa ngokuxutshwa kwesivinini esikhulu (3) ukuze kuhlanganiswe izinto ezingavuthiwe zibe ingxube eyomile esatshalaliswe ngokufanayo.Izinga lokushisa lokuxuba elizungeze i-120 ° C lifinyelelwa ngokushisa okuhlangene.Ezigabeni ezahlukahlukene zenqubo yokuxuba, izithasiselo ziyancibilika futhi zimboze kancane kancane ama-PVC polymer granules.Ngemva kokufinyelela izinga lokushisa elidingekayo, inhlanganisela ikhishelwa ngokuzenzekelayo egumbini lokupholisa elinciphisa ngokushesha izinga lokushisa libe ngu-50°C, ngaleyo ndlela livumele ukuhlanganisa ukuthi kudluliselwe endaweni yokugcina emaphakathi (4) lapho kufinyelelwa khona ngisho nezinga lokushisa nokulingana.

Inhliziyo yenqubo, i-extruder (5), inomphongolo olawulwa izinga lokushisa, ozoniwe lapho uzungezisa khona “izikulufu” ngokunemba.Izikulufu zesimanje ze-extruder zingamadivayisi ayinkimbinkimbi, aklanywe ngokucophelela ngezindiza ezihlukene ukuze alawule ukucindezelwa nokugunda, okuthuthukiswe ezintweni, phakathi nazo zonke izigaba zenqubo.I-twin counter-rotation screw configuration esetshenziswa yibo bonke abakhiqizi abakhulu inikeza ukucubungula okuthuthukisiwe.

I-dryblend ye-PVC ibalwa ngamamitha emgqonyeni nasezikulufini, ezibe seziguqula inhlanganisela eyomile ibe yisimo esidingekayo "sokuncibilika", ngokushisa, ukucindezela kanye nokugunda.Ngesikhathi sokuhamba kwayo eduze nezikulufu, i-PVC idlula ezindaweni eziningi ezicindezela, i-homogenise futhi ikhiphe umfudlana oncibilikayo.Indawo yokugcina inyusa ingcindezi yokukhipha inyibiliki ngekhanda kanye nesethi ye-diesel (6) eyakhiwe ngokuhambisana nobukhulu bepayipi elidingekayo kanye nezici zokugeleza zomfudlana oncibilikayo.Uma ipayipi lishiya i-extrusion kufa, lilinganiswa ngokudlula kumkhono wokulinganisa onembayo onevacuum yangaphandle.Lokhu kwanele ukwenza lukhuni ungqimba lwangaphandle lwe-PVC nokubamba ububanzi bepayipi ngesikhathi sokupholisa okokugcina egunjini lokupholisa amanzi elilawulwayo (8).

Ipayipi lidonswa ngokulinganisa kanye nokusebenza kokupholisa umdobi noma ukulikhipha (9) ngesivinini esingaguquki.Ukulawula isivinini kubaluleke kakhulu uma lesi sixhobo sisetshenziswa ngoba ijubane elidonswa ngalo ipayipi lizothinta ukushuba kodonga lomkhiqizo oqediwe.Esimeni sepayipi elihlangene lerabha eliyindandatho yerabha ukudonsa kuyancishiswa ngezikhathi ezifanele ukuze kushube ipayipi endaweni yesokhethi.

Iphrinta esemgqeni (10) imaka amapayipi ngezikhathi ezithile, ngokuhlonzwa ngokosayizi, isigaba, uhlobo, idethi, inombolo evamile, nenombolo ye-extruder.Isaha elizisikayo (11) lisika ipayipi libe ngobude obudingekayo.

Umshini wezinsimbi wakha isokhethi ekugcineni kobude bepayipi ngalinye (12).Kunezinhlobo ezimbili ezijwayelekile zesokhethi.Epayipini elihlanganisiwe lenjoloba, kusetshenziswa i-mandrel egoqekayo, kanti i-mandrel ethafeni isetshenziselwa amasokhethi ahlanganisiwe e-solvent.Ipayipi leringi lerabha lidinga i-chamfer ku-spigot, esetshenziswa esiteshini samasaha noma iyunithi yokushaya.

Umkhiqizo oqediwe ugcinwa ezindaweni zokugcina ukuze uhlolwe futhi uhlolwe ilabhorethri yokugcina nokwamukelwa kwekhwalithi (13).Konke ukukhiqizwa kuyahlolwa futhi kuhlolwe ngokuvumelana nezinga elifanele lase-Australia kanye/noma nezicaciso zomthengi.

Ngemva kokuhlolwa nokwamukelwa, ipayipi ligcinwa ukuze lilinde ukuthunyelwa kokugcina (14).

Kumapayipi e-PVC (PVC-O) aqondiswe kahle, inqubo yokukhipha ilandelwa inqubo yokwandisa eyengeziwe eyenzeka ngaphansi kwezimo ezichazwe kahle nezilawulwa ngokucophelela zokushisa nokucindezela.Kungesikhathi sokunwetshwa lapho ukuqondiswa kwamangqamuzana, okunikeza amandla aphezulu ajwayelekile e-PVC-O, kwenzeka.

Ukubunjwa komjovo

Ukufakwa kwe-PVC kwenziwa ngokubunjwa komjovo wengcindezi ephezulu.Ngokuphambene ne-extrusion eqhubekayo, ukubumba kuyinqubo ye-cyclic ephindaphindayo, lapho "ukudubula" kwempahla kulethwa kusikhunta emjikelezweni ngamunye.

Okubalulekile kwe-PVC, okungaba kuyingxube eyomile yempushana noma ifomu elihlanganisiwe eliyimbudumbudu, amandla adonsela phansi asuka ku-hopper ephezu kweyunithi yomjovo, angene emgqonyeni wendlu yesikulufu esiphindaphindayo.

Umgqomo ukhokhiswa inani elidingekayo lepulasitiki ngesikulufu esizungezisayo futhi sidlulisele okokusebenza ngaphambili komgqomo.Indawo yesikulufu isethwe “kusayizi wokudubula” onqunywe kusengaphambili.Phakathi nalesi senzo, ingcindezi nokushisa "i-plasticise" impahla, manje esesimweni sayo esincibilikile, ilindele ukujova esikhunjeni.

Konke lokhu kwenzeka phakathi nomjikelezo wokupholisa wesithombe esidlule.Ngemuva kwesikhathi esibekiwe, isikhunta sizovuleka futhi ukufakwa okubunjiwe okuqediwe kuzokhishwa esikhunjeni.

Isikhunta sibe sesivala futhi ipulasitiki encibilikisiwe engaphambili komgqomo ijovwa ngaphansi kwengcindezi ephezulu ngesikulufu esisebenza njenge-plunger.Ipulasitiki ingena esikhunjeni ukuze yakhe ukufakwa okulandelayo.

Ngemuva komjovo, ukushajwa kabusha kuyaqala ngenkathi okokufaka okubunjiwe kuqhubeka emjikelezweni wakho wokupholisa.

Isikhathi sokuthumela: Jun-23-2022