Izinto ezingavuthiwe zokukhiqiza amapayipi e-PVC

Izinto ezisetshenziswayo zokukhiqiza amapayipi e-PVC,

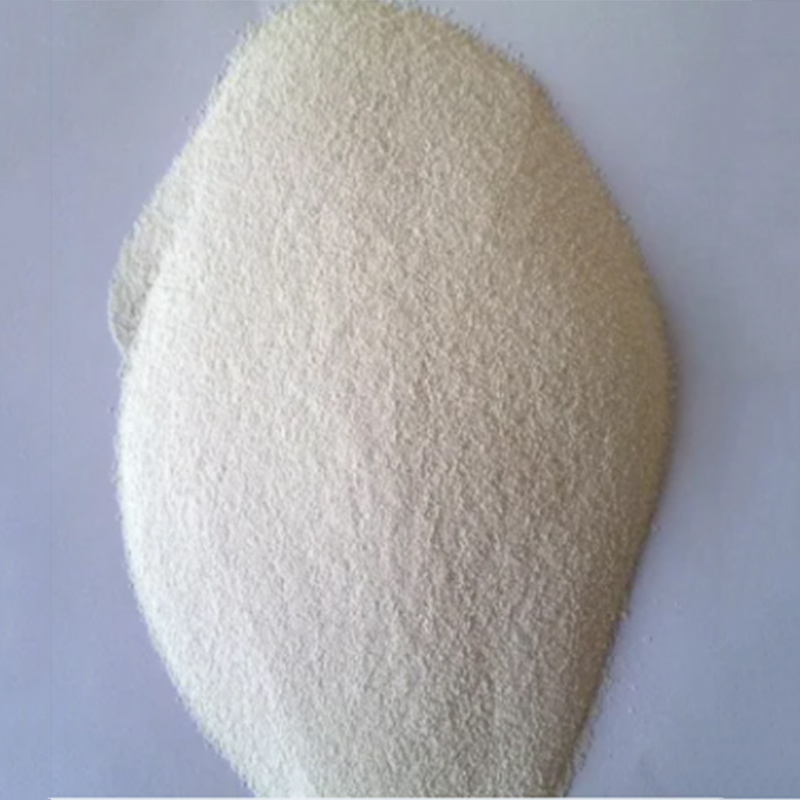

I-PVC Resin, PVC ukukhiqiza ipayipi,

I-S-1000 polyvinyl chloride resin ikhiqizwa inqubo ye-polymerization yokumiswa kusetshenziswa i-vinyl chloride monomer njengento eluhlaza.Iwuhlobo lwenhlanganisela ye-polymer enobuningi obuhlobene obungu-1.35 ~ 1.40.Iphuzu layo lokuncibilika licishe libe ngu-70 ~ 85℃.Ukungaqini kahle kokushisa nokumelana nokukhanya, ngaphezu kuka-100 ℃ noma isikhathi eside ngaphansi kwelanga i-hydrogen chloride iqala ukubola, ukukhiqizwa kwepulasitiki kudinga ukwengeza izinza.Umkhiqizo kufanele ugcinwe endaweni eyomile futhi engenawo umoya.Ngokwenani le-plasticizer, ukuthamba kwepulasitiki kungalungiswa, futhi i-resin yokunamathisela ingatholakala nge-emulsion polymerization.

IBanga S-1000 lingasetshenziswa ukukhiqiza ifilimu ethambile, ishidi, isikhumba esenziwe ngumuntu, amapayipi, ibha enomumo, ibhongo, amapayipi okuvikela ikhebula, ifilimu yokupakisha, isoli nezinye izimpahla ezithambile.

Amapharamitha

| Ibanga | I-PVC S-1000 | Ukuphawula | ||

| Into | Inani lesiqinisekiso | Indlela yokuhlola | ||

| Idigri ye-polymerization emaphakathi | 970-1070 | GB/T 5761,Isithasiselo A | K inani 65-67 | |

| Ukuminyana okusobala, g/ml | 0.48-0.58 | Q/SH3055.77-2006, Isithasiselo B | ||

| Okuqukethwe kwe-Volatiles (amanzi afakiwe), %, ≤ | 0.30 | Q/SH3055.77-2006, Isithasiselo C | ||

| Ukumuncwa kwe-plasticiser ye-resin engu-100g, g, ≥ | 20 | Q/SH3055.77-2006, Isithasiselo D | ||

| Izinsalela ze-VCM, mg/kg ≤ | 5 | I-GB/T 4615-1987 | ||

| Ukuhlolwa % | 2.0 | 2.0 | Indlela 1: GB/T 5761, Isithasiselo B Indlela 2: Q/SH3055.77-2006, Isithasiselo A | |

| 95 | 95 | |||

| Inombolo ye-Fisheye, No./400cm2, ≤ | 20 | Q/SH3055.77-2006, Isithasiselo E | ||

| Inombolo yezinhlayiya zokungcola, Cha., ≤ | 16 | I-GB/T 9348-1988 | ||

| Ubumhlophe (160ºC, 10minutes kamuva), %, ≥ | 78 | I-GB/T 15595-95 | ||

Amapayipi e-PVC akhiqizwa nge-extrusion ye-PVC yempahla eluhlaza, futhi ngokuvamile alandela izinyathelo ezifanayo zemisebenzi evamile yokukhipha amapayipi:

1.Ukuphakelwa kwempushana eluhlaza ebizwa ngokuthi i-resin kanye ne-filler ku-PVC twin screw extruder;

2. Ukuncibilika nokushisa ezindaweni eziningi ze-extruder;

3. Ukukhipha idayisi ukuze kube ipayipi;

4.Ukupholisa kwepayipi elimise (ngokufafaza amanzi epayipini);futhi

5. Ukusika amapayipi e-PVC ubude obufunayo.

Izinto zokusetshenziswa zokukhiqiza amapayipi e-PVC yi-resin kanye nesigcwalisi (ikakhulukazi i-calcium carbonate, noma eyaziwa ngokuthi amatshe).Ingxube evamile yi-1 kilogram (kg) ye-resin ne-1 kilogram yokugcwalisa.Izinqubo zokukhiqiza ngokuvamile zizenzakalela, lapho abasebenzi bephakela izinto zokusetshenziswa ekuqaleni kwenqubo, baqapha izinga lokushisa enqubweni futhi babheke umkhiqizo wokugcina ukuthi awunamaphi amaphutha asobala ngaphambi kokupakisha nokuthumela kumakhasimende.Bonke abasebenzi baqeqeshiwe futhi bayakwazi ukwenza yonke le misebenzi ngekhono.Impahla eyinhloko yokwenziwa kwamapayipi e-PVC yinto eyimpuphu ebizwa nge-PVC resin.