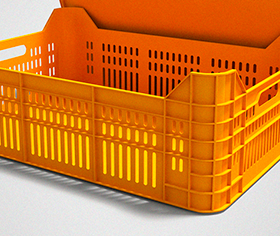

Ukubumba komjovo we-HDPE kwekhreyithi

I-HDPE umjovo wokubumba ikhreyithi,

I-HDPE Yekhreyithi, Ukubumba umjovo we-HDPE,

Ikhreyithi lepulasitiki elakhiwe nge-high density polyethylene (HDPE) umjovo wokubumba wokuhlanganisa kokuqala.

I-Crate ibunjwe ngezinto ezikhethekile ze-HDPE ukuze kuzuzwe ukuqina okukhulu.Isivinini sokuncibilika sezinto ezikhethekile singama-3.6-4.5 g/10 amaminithi, ukungezwani kungaphezu kuka-25 Pa, amandla aqinile angaphezulu kuka-60% futhi amandla okunciphisa angaphezulu kwama-40 Pa. Ngokuvamile impahla ye-HDPE ayinamagatsha amancane, kodwa into entsha ekhethekile. esetshenziselwa amakhreyithi kuyinikeza amandla anamandla e-intermolecular namandla aqinile kune-LDPE.Ubuso bayo buqinile futhi bubonisa ngale, futhi ingakwazi ukumelana nezinga lokushisa eliphezulu (120 C/248 F isikhathi esifushane, 110 C /230 F ngokuqhubekayo), ukuze ifinyelele imfuneko yokuqina.Kumele kuqashelwe ukuthi i-HDPE, ngokungafani ne-polypropylene, ayikwazi ukumelana nokucindezela okuphezulu okujwayelekile.

Ukubunjwa komjovo

Ukubumba umjovo kuyinqubo yokwenza ipulasitiki ehlanganisa ukujova izinto zokusetshenziswa zepulasitiki ezincibilikisiwe ekamelweni elivaliwe noma isikhunta.Le nqubo inezinqubo ezintathu ezibalulekile:

Ukugaya nokushisa ipulasitiki kuze kube yilapho igeleza ngaphansi kwengcindezi.

Ukujova ipulasitiki ngaphakathi kwesikhunta bese uyivumela ukuthi iphole.

Ukuvula isikhunta ukukhipha isitsha sepulasitiki.

I-extruder yohlobo lwe-screw ephindaphindayo isetshenziswa ikakhulukazi embonini ukwenza ipulasitiki yokwenza ingxube;kukhona ukuxuba okuphindaphindiwe nokuxova i-scruder yohlobo lwe-screw.Lapho ipulasitiki (izinto zokusetshenziswa) isilungele ukujovwa, njengoba isikulufu sihamba, iphusha ipulasitiki iphume ku-extruder futhi ingene esikhunjeni.

Ukwenza umumo odingwa yikhasimende, kunesikhunta esiklanywe ngezici ezithile eziqukethe umumo othile.Ngokujwayelekile iqukethe izingxenye ezimbili noma amahhafu anezici ezifanayo.Enye inamandla okunyakaza noma ihlala inganyakazi kuyilapho enye ingxenye yesikhunta inganyakaza.Ngemuva kokubumba, enye ingxenye ingahamba ngaleyo ndlela ukuze ikhulule umkhiqizo esikhunjini ngendlela engashintshiwe.Isikhunta siqukethe izimbobo noma amashaneli amaningana noma amaningi.Lezi zisetshenziselwa ukwethula ipulasitiki esikhunjeni, ikhiphe umoya, futhi ivumele ipulasitiki ukuthi iphume esibunjeni.

Ukubumba komjovo kukhawulele ukukhiqizwa uma kuza ekukhiqizweni kweziqukathi ezinohlangothi olulodwa noma amakhreyithi.Obhavu, amapheya, izinkomishi, izitsha zokudla, nezitsha kuyizibonelo.Ngokwako, ukubumba komjovo akufanelekile ukukhiqiza imikhiqizo evaliwe, engenalutho njengamabhodlela epulasitiki yingakho kulungele ukukhiqizwa kwamakhreyithi avulekile.Ukukhiqiza le mikhiqizo, kusetshenziswa igesi ye-inert.Lokhu kusetshenziswa ngoba kuzosusa ukusabela okungaba khona esikhunjeni lapho inqubo ihamba.Lokhu kungeniswa esibunjeni esigcwele ingxenye yepulasitiki encibilikisiwe.Lokhu kuphushela ipulasitiki phezu kwesikhunta sikhiqize ingxenye engenalutho.Le nqubo ibizwa ngokuthi i-gas-assisted injection molding.

Isicelo

Ibanga lokubumba umjovo we-HDPE lisetshenziselwa ukwenza iziqukathi ezisebenziseka kabusha, njengamakesi kabhiya, amakesi eziphuzo, amakesi okudla, amakesi emifino namakesi amaqanda futhi ingase isetshenziselwe ukwenza amathreyi epulasitiki, iziqukathi zezimpahla, izinto zikagesi zasendlini, ukusetshenziswa kwempahla yansuku zonke kanye nezincane- izitsha zokudla odongeni.Ingasetshenziswa futhi ekukhiqizeni imigqomo esetshenziswa yizimboni, imigqomo kadoti namathoyizi.Ngokusebenzisa inqubo yokubumba ye-extrusion kanye nokucindezelwa nokubunjwa komjovo, ingasetshenziswa ukukhiqiza izigqoko zamanzi ahlanzekile, amanzi amaminerali, isiphuzo setiye namabhodlela esiphuzo sejusi.